Coverslip Selection

Background

Spending time optimizing your staining and labelling techniques can all be for nothing, if you don’t use the right coverslips for imaging. Coverslips are not made equally, there are differences between the material, and the thickness (as well as any coating added), and therefore knowing which ones to use is really important.

Coverslip thickness

It is important to match the right coverslip to the right imaging objective fitted to the microscope you plan to use. For all microscopes in IMB it is important to use #1.5 coverslips.

| Coverslip # | Thickness |

|---|---|

| 0 | 0.085 - 0.13 mm |

| 1 | 0.13 - 0.16 mm |

| 1.5 | 0.16 - 0.19 mm |

| 2 | 0.19 - 0.23 mm |

| 3 | 0.25 - 0.35 mm |

| 4 | 0.43 - 0.64 mm |

Microscope Objectives

One of the many pieces of information written onto every objective is the designed (or expected) coverslip thickness. On the following 40x oil immersion objectives from every major vendor, the number 0.17 can be found which refers to 0.17mm coverslip thickness expected.

Source: Douglas Cromey, University of Arizona

Why should you care?

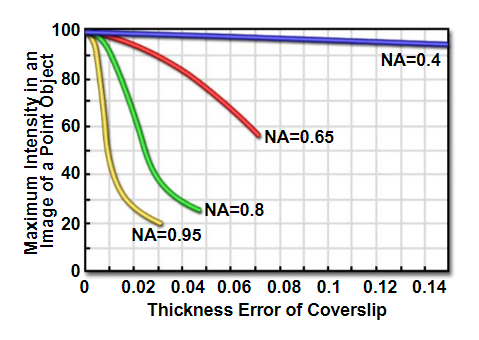

Using the incorrect coverslip for the objective used on the microscope will affect your final image. The following graph shows the degradation of signal intensity for different NA objectives for coverslips of varying thickness. The take home message is anything above an NA of 0.4 (~our 20x objectives and above) will lose up to 80% of the signal intensity.

For example, if you are using a 40x Air objective (Nikon Deconvolution, Andor Dragonfly, Leica SP8, etc) and using a #1 coverslip you could expect to lose 60-80% of the fluorescence signal!

Source: https://www.microscopyu.com/microscopy-basics/coverslip-correction

Note most of the coverslips stocked in the QBP store are #1 coverslips. There is however one product from Zeiss that is stocked (D766). Most Mattek and Ibidi dishes for live imaging are #1.5 by default.