3D Printing @ IMB

Background

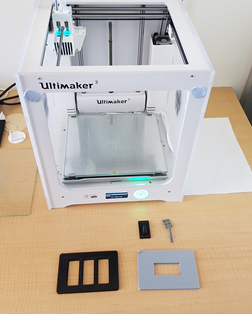

In order to meet the growing demands of our users and the different sample chambers and dishes required for their experiments, the IMB microscopy facility has purchased an Ultimaker 3 3D printer.

3D printing works by heating up different plastic materials and extruding them through a small, movable nozzle to build up a 3D object layer, by layer.

Ultimaker 3 Specifications

-

Dual Extrusion (2 different print heads, capable of multi-colour/material printing)

-

Build volume (single material 215x215x200mm; dual material 197x215x200mm)

-

Filament diameter: 2.85mm

-

Layer resolution: 0.4mm nozzle: 20-200 micron

-

Step accuracy: 12.5x12.5x2.5 micron

-

Build speed: upto 24mm^3/s

-

Nozzle temperature: 180-280 degrees C

-

Build plate temperature: 20-100 degrees C

Current Filament Stock

-

Black PLA

-

Green PLA

-

Silver PLA

-

White PLA

-

Black ABS

-

Polypropylene

-

Nylon

-

PVA

-

White Breakaway

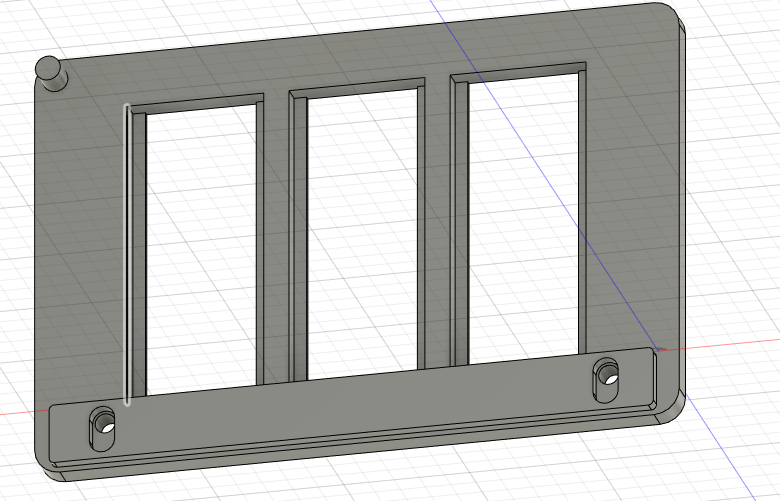

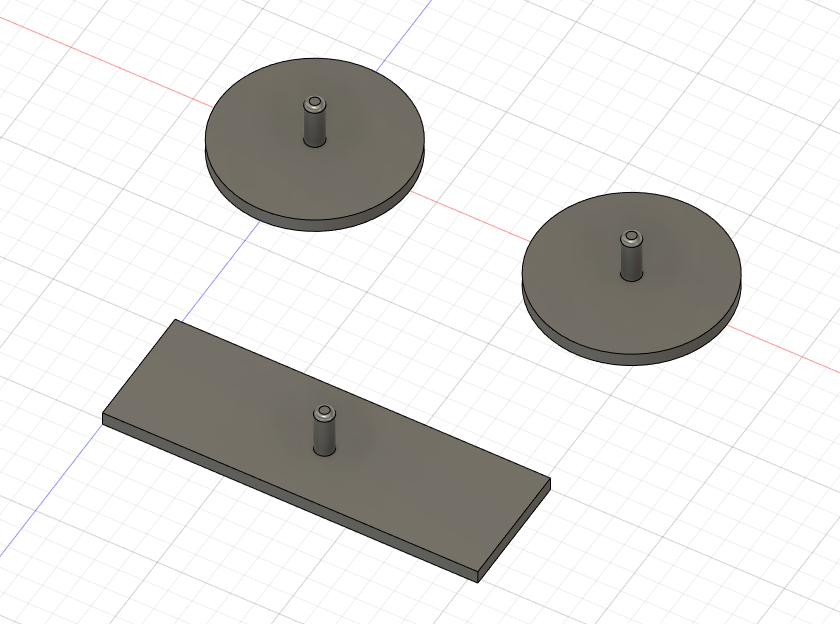

Example Projects

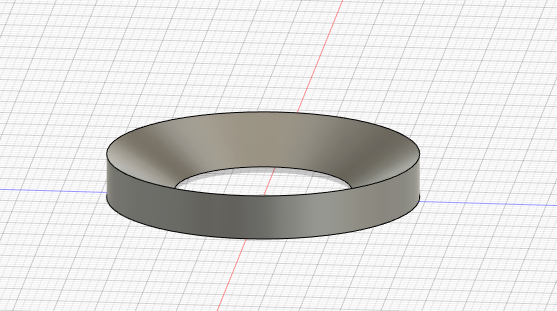

Zebrafish well agarose stamp

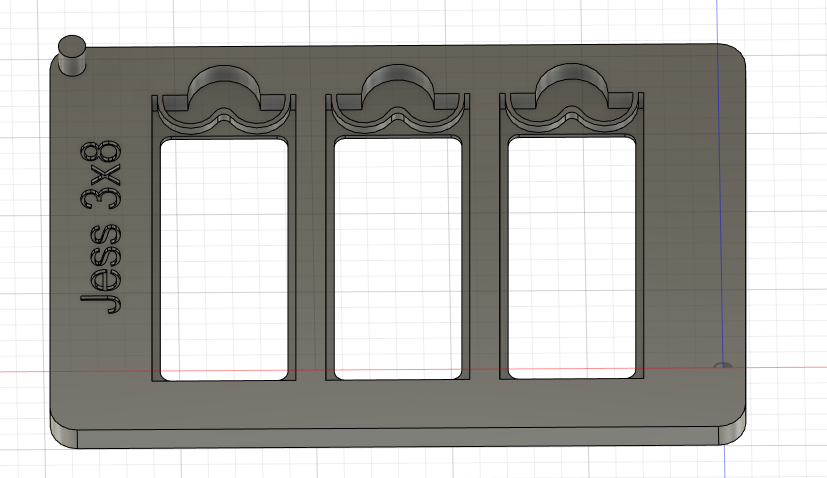

3x8 well chamber slide stage insert

Multi-well chamber insert

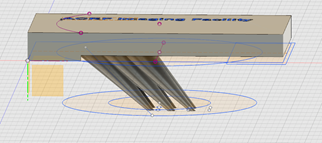

Microscope stage inserts for CO2 incubation.

Plastic sample holder for electrophysiology imaging.