It’s no secret that the world has a problem with plastic. Honeybees are making nests entirely from plastic, remote beaches on tiny islands are covered in tonnes of plastic and sea creatures get ensnared in it and ingest it.

Plastic’s benefits – including that it’s light, durable and cheap – have fed our addiction to the non-biodegradable substance and left us with a huge amount of plastic waste piling up on land and in the ocean.

While reducing our plastic use as individuals is helpful, large-scale change is needed to truly address the problem. Professor Ben Hankamer and Dr Nasim Amiralian, from IMB’s Centre for Solar Biotechnology, led a team that examined the future of plastics and how tiny species of algae and bacteria may help us produce more environmentally friendly versions.

The problem with plastic

Across the globe, huge amounts of plastic have been generated since it was first produced on a mass scale in the middle of last century. A 2019 research article estimates that we’ve produced more than 8.3 metric tonnes of plastic up to 2015, with 6.3 tonnes ending up as waste, enough to build 2269 plastic replicas of the Great Pyramids of Giza.

As the global population increases and living standards across the world also improve, this demand for plastic products from packaging to medical devices is only going to rise. By 2050, it’s expected that the total of plastic waste will be closer to 12 metric tonnes.

“Perhaps the most graphic example of the global scale of plastic pollution is the Great Pacific Garbage Patch,” Professor Hankamer writes in a review of plastics that was published in Trends in Plant Science. This patch is essentially a 1.6 million km2 plastic soup, one of five made up of some of the 5.25 trillion pieces of garbage that float in our oceans and are brought together by currents.

Giant patches of garbage floating in the ocean aren’t just a concern for sea life: this proliferation of plastic in the marine environment also has health impacts for us land-dwellers. The most common plastic particles in the ocean are less than 5mm in diameter. These microplastics are entering the food chain, and have been found in a range of foods and drinks, including fish, beer, salt and bottled water. Although there is more research to be done in this area, there is concern that microplastic exposure is causing an increase in complications in diseases such as inflammation, and that the accumulation of microplastics in the body could lead to toxic effects.

The solution: bio-based plastics

While there is a growing recognition of our need to use more environmentally friendly materials, the ubiquity of plastics and their undoubted advantages mean it can be difficult for us as individuals to reduce our plastic use sufficiently to make a collective global difference. One promising answer to the plastic problem is thus to replace non-degradable plastic manufactured from petroleum based oil with sustainably produced and degradable bioplastics, that is, plastics produced by living organisms such as plants, algae and bacteria.

“All plastics are ultimately composed of very large molecules called polymers,” Dr Amiralian said. “The polymers traditionally used in most forms of plastic – such as polyethelene, which is used in plastic bags - are synthetically produced. But plants, bacteria and algae produce a wealth of natural bio-based polymers, which can be mixed in a very large number of combinations. By chemically modifying these polymers and introducing additives derived from renewable resources, we can manufacture a huge variety of green plastics with different characteristics.”

These plastics have the advantages of traditional plastic without the environmental price tag. The downside? While bioplastics currently do exist, some are produced from plants that are also used as crops, meaning they compete for arable land, fresh water and food use.

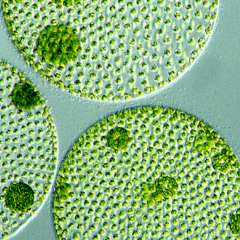

With the world’s population forecast to reach 9.8 billion by 2050, with associated increased demand for fresh water and food, any solution must use non-arable land (or the oceans) and minimise the use of fresh water or food crops. One solution is to use agricultural waste as a source of bioplastics. Another is the use of marine macroalgae (e.g. seaweeds) and microalgae (e.g. unicellular green algae).

This is where Professor Ben Hankamer and the Centre for Solar Biotechnology team come in. They are some of the pioneers of harnessing microalgae to produce fuel, food and high-value products. Just like plants, algae use photosynthesis to absorb CO2 and produce chemicals, all powered by the sun. They are investigating the ability of algae to manufacture both non-degradable and degradable plastics.

Non-degradable vs bio-degradable plastics

Although non-degradable plastics don’t sound like much of a win for the environment, Professor Hankamer explains that they do have a role to play in a carbon-friendly future.

“Instead of single-use plastics that often become waste, bio-based non-degradable plastics can play an important role as carbon sinks. The CO2 that is absorbed as part of photosynthesis is taken out of the atmosphere and can be stored in materials that are made into sustainable, long-lasting infrastructure such as pipes, building materials and road surfaces, helping governments and nations to reduce their CO2 emissions.”

In addition fully bio-degradable bioplastics can be used to create products with a shorter life span with a minimal environmental impact.

“The timescale over which these plastics break down can theoretically be tailored to the purpose of the product, for example, engineering a soft drink bottle that will fully degrade in a few years,” Dr Amiralian said.

“Legislated national and international standards are critical to ensure these bioplastics can degrade to CO2 and water and don’t release toxic by-products. This degradation needs to occur not just in industrial composting systems, but also in home composting and terrestrial and aquatic environments, to ensure they degrade wherever plastics waste ends up. These products would be carbon-neutral, taking CO2 out of the atmosphere during the production process and releasing it back once the bioplastic has degraded.”

Where to from here?

Although the technology exists to produce bio-based plastics, their performance needs to be improved and their cost needs to be reduced before the vision of a future with sustainable plastics can truly become reality. Professor Hankamer’s team is using tools to make tiny and precise changes to the genetic code of algae to enable these species to produce useful products in a closed system.

This work is conducted in parallel with detailed economic analyses of scaled up systems to identify the most valuable production streams and their capital and operational costs to deliver good economic, social and environmental outcomes. The first bioplastics to go into wide production are likely to be specialist higher-value products such as those required for biomedical devices. As innovation drives down the production cost, more affordable bioplastics could move into the mainstream.

“Governments could assist the transition to a more sustainable future through well designed policies that account for the cost of externalities – such as the cost of recycling plastic, environmental degradation and health-related costs. In this way bioplastics would become more cost-effective, significantly speeding the transition to an economy involving biological production,” Professor Hankamer said.

So there may be no need to forgo the benefits of plastic after all, just to let algae make the world greener.

Your gift can help progress research at the Centre for Solar Biotechnology or fund blue-sky research at IMB through the Ignite Innovation Awards.