As Australia becomes one of only three countries to approve cultivated meat for sale, researchers at The University of Queensland’s Institute for Molecular Bioscience (IMB) have made a discovery that could help the emerging industry scale sustainably and overcome one of its biggest hurdles: cost.

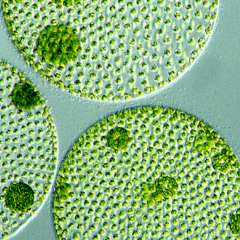

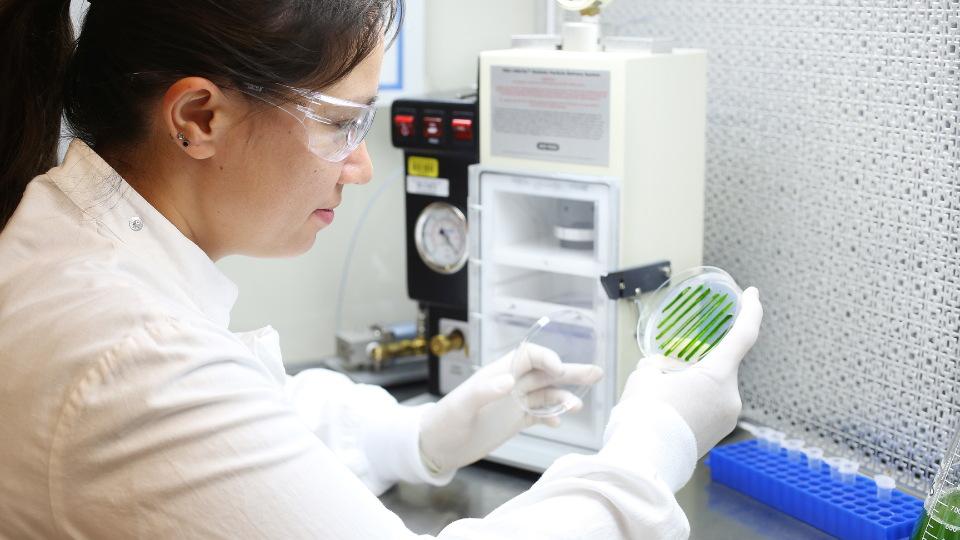

In a new study, Dr Melanie Oey and her team have shown that muscle cells co-cultivated with a locally isolated algae strain—Chlorella BDH-1—grow faster, live longer, and require fewer expensive nutrients, offering a practical way to reduce production costs in lab-grown meat.

“Growing meat in the lab is expensive, largely due to the nutrients and oxygen the cells need, and the waste they produce,” said Dr Oey. “Our work shows that a simple, plant-based partner—algae—can solve multiple problems at once.”

“We saw over 80% more cell growth, cultures remained viable for six days without a media change, producing 2-3 times more viable cells than algae-free controls. And a 50% reduction in the need for costly and ethically challenging foetal bovine serum,” said Dr Oey.

How does it work?

The algae act like tiny life-support systems. Through photosynthesis, they naturally produce oxygen and remove waste, creating a more supportive environment for the muscle cells to thrive.

This discovery comes at a crucial time, as growth medium currently accounts for up to 90% of cultivated meat production costs.

“In the human body, blood delivers oxygen and removes waste. But in a lab setting, you don’t have that system,” explained Dr Oey. “By adding algae, we’re essentially creating a mini-symbiosis — like corals. The algae provide oxygen and take away waste, helping the cells grow better.”

The results were remarkable. And crucially, the algae strain doesn’t consume glucose, so it doesn’t compete with the mammalian cells for fuel.

The team’s work also supports more sustainable science across the board; reducing lab waste, extending the use of culture media, and eliminating frequent media changes, all of which contribute to lower costs and less environmental impact.

“It’s like your muscles during exercise,” Dr Oey explained. “When you don’t get enough oxygen, lactate builds up and your muscles get sore. The same thing happens in cell cultures. By using algae to provide oxygen, we avoid that build-up, and the cells can grow more efficiently and with less stress.”

What does this mean for the future?

While the implications for cultivated meat are clear, the potential applications go far beyond food.

“This approach could be applied to any mammalian cell system that requires oxygen and produces waste—which is most of them,” said Dr Oey.

Broad applications could include:

⦁ Tissue engineering & regenerative medicine. Improved cell growth could accelerate the development of 3D tissues, grafts, and organoids.

⦁ Pharmaceutical manufacturing. Companies could grow vaccine- and biologic-producing cells more efficiently, with lower overheads and fewer inputs.

⦁ Lab-based research. A greener, cost-effective alternative for maintaining mammalian cells, especially valuable in resource-limited settings.

⦁ Sustainable science. By reducing waste and animal-derived inputs, this method supports more ethical and environmentally responsible research.

“It’s a simple idea with broad potential,” Dr Oey explained. “By working with nature, using algae to improve the cellular environment, we’ve created a scalable way to support healthier, longer-lasting, and more efficient cell cultures.”

Whether it’s building a better burger, growing tissue for healing, or scaling up drug manufacturing, algae could become an essential partner in the future of biotechnology.

To find out more or explore potential collaboration opportunities, please contact Dr Melanie Oey at melanie.oey@uq.edu.au.

Read the full paper here.